December 2006

In

the never ending story of the reconstruction of the RL3 No.

20787 a new and hopefully the last chapter is opened: the

locomotive stands without its front axle on sleeper piles in the

workshop. In order to eliminate the pressure between the rods

and the wheels, in last autumn the axle boxes were adjusted by

plates. After this it was only possible to mount the rod on one

side, the crankpins of the wheels and the jackshaft on the other

side were not in one line. The fact was that the wheels of the

front axle were not in an exact 90° position. Today we can

only assume the reason of this deviation, may be the loco had

a small accident by a stone, rolling under the rod of the running

machine. May be this circumstance saved the loco until today:

all of her usable sisters have been sold and later scrapped in

the seventies. Only the 20787 remained in the abandoned brick

yard. Now it's necessary to dismount one wheel and to remount

it in the right position. It will not be an easy task but it will

be solvable.

In

the never ending story of the reconstruction of the RL3 No.

20787 a new and hopefully the last chapter is opened: the

locomotive stands without its front axle on sleeper piles in the

workshop. In order to eliminate the pressure between the rods

and the wheels, in last autumn the axle boxes were adjusted by

plates. After this it was only possible to mount the rod on one

side, the crankpins of the wheels and the jackshaft on the other

side were not in one line. The fact was that the wheels of the

front axle were not in an exact 90° position. Today we can

only assume the reason of this deviation, may be the loco had

a small accident by a stone, rolling under the rod of the running

machine. May be this circumstance saved the loco until today:

all of her usable sisters have been sold and later scrapped in

the seventies. Only the 20787 remained in the abandoned brick

yard. Now it's necessary to dismount one wheel and to remount

it in the right position. It will not be an easy task but it will

be solvable.

Unfortunately

the coiled springs by O&K tend to brake frequently with increasing

age. So far I used spiral springs as substitute, which were built

for heavy mining cars. Because the springs of the locomotives

are free visible, there was the goal to rebuilt new "old"

springs already for a long time. In order to receive a favourable

price, four orderers joined. So could be manufactured an accordingly

large number of springs (30). The Bischoff

company in Stassfurt delivered an excellent work!

Unfortunately

the coiled springs by O&K tend to brake frequently with increasing

age. So far I used spiral springs as substitute, which were built

for heavy mining cars. Because the springs of the locomotives

are free visible, there was the goal to rebuilt new "old"

springs already for a long time. In order to receive a favourable

price, four orderers joined. So could be manufactured an accordingly

large number of springs (30). The Bischoff

company in Stassfurt delivered an excellent work!

November 2006

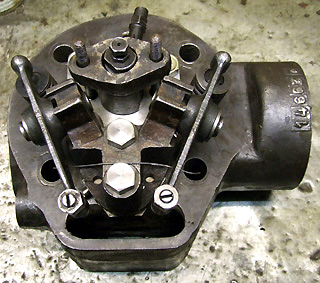

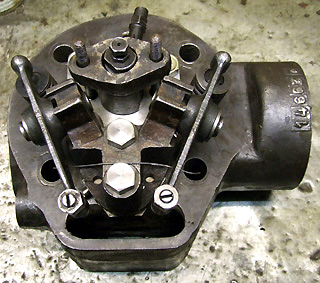

The motor that's present mounted on the

MD1 was originally as an exchange engine on the type M

loco. Together with their it had been on the ground of a shut

down quarry for approx. 30 years . Before this "scrapping"

somebody had dismantled still the cylinder head and the water

pump. These circumstances were very bad for the motor and thus

it wasn't planned to restore it. That did also not change when

the MD1 with an exchange engine came into the collection, because

the missing cylinder head was not replaceable. But persistent

asking around led to the fact that a cylinder head could be bought

after some years. However, the existing attachments (rocker lever

block and nozzle holder) of MD2 and RL1c did not fit to the head,

which comes probably still from a type MD motor. After longer

puzzle about it, how the problem was to be solved by a specialty

firm here in Dresden. They manufactured an adapter that the accessories

makes suitable to the cylinder head.

_

_ _

_

October 2006

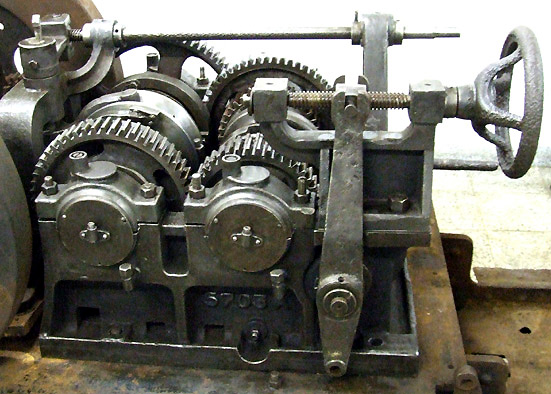

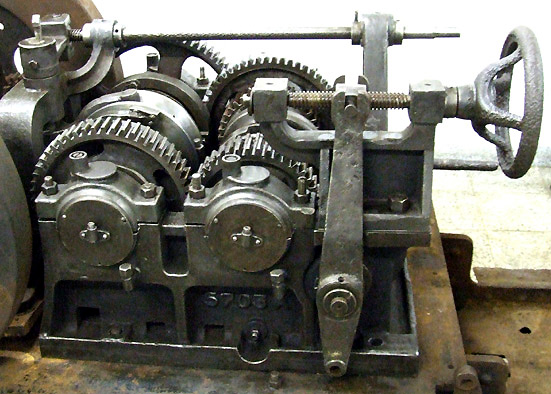

Because the restoration of the benzene

locomotive is very complex and some difficulties are predictable

, it doesn't exist a schedule for this task. The work takes place

in small steps and rather besides. As the first stage this way

the gear box was divided and re-mounted. Only a disk, which broke

when forcing and the bearing bushes in two gear wheels had to

be renewed, all other parts can be used furthermore. For the refurbishing

of the locomotive framework the gear box is removable as a whole

of the locomotive later.

_

_

May 2006

There is new acquisition in the collection:

a SCHÖMA Lo20. It looks with their porthole windows

a little as from an animated cartoon. The propulsion principle

with pendular axle and Cardan drive is remarkable. If the gauge

of the locomotive will be changed from 890mm to 600mm, it is to

be used in Glossen, because it is similar to the DIEMA locos working

there in former times.

_

_

February 2006

The French RL1a was functional

again after the repair of the engine, but it inclined to derail

and could not be pushed by hand not. The reason for it was that

the bearing surfaces of the wheels had strongly run in. Thus resulted

different wheel diameters, which had the consequence to force

strong the chain between both axes. When the axes were dismounted,

it turned out that the wheel circumferences were far away from

the ideal circle. Due to the extreme hardness of the bearing surfaces

(the material was cold-rolled over decades in use) it was necessary

to work with the friction disk, before the axes could on the centre

lathe. The diagonal grooves were removed again with a particularly

hard roughing disk. Partially up to 15mm material from the radius

were taken away. Fortunately the technical designers had planned

enough reserves.

_

_

In

the never ending story of the reconstruction of the RL3 No.

20787 a new and hopefully the last chapter is opened: the

locomotive stands without its front axle on sleeper piles in the

workshop. In order to eliminate the pressure between the rods

and the wheels, in last autumn the axle boxes were adjusted by

plates. After this it was only possible to mount the rod on one

side, the crankpins of the wheels and the jackshaft on the other

side were not in one line. The fact was that the wheels of the

front axle were not in an exact 90° position. Today we can

only assume the reason of this deviation, may be the loco had

a small accident by a stone, rolling under the rod of the running

machine. May be this circumstance saved the loco until today:

all of her usable sisters have been sold and later scrapped in

the seventies. Only the 20787 remained in the abandoned brick

yard. Now it's necessary to dismount one wheel and to remount

it in the right position. It will not be an easy task but it will

be solvable.

In

the never ending story of the reconstruction of the RL3 No.

20787 a new and hopefully the last chapter is opened: the

locomotive stands without its front axle on sleeper piles in the

workshop. In order to eliminate the pressure between the rods

and the wheels, in last autumn the axle boxes were adjusted by

plates. After this it was only possible to mount the rod on one

side, the crankpins of the wheels and the jackshaft on the other

side were not in one line. The fact was that the wheels of the

front axle were not in an exact 90° position. Today we can

only assume the reason of this deviation, may be the loco had

a small accident by a stone, rolling under the rod of the running

machine. May be this circumstance saved the loco until today:

all of her usable sisters have been sold and later scrapped in

the seventies. Only the 20787 remained in the abandoned brick

yard. Now it's necessary to dismount one wheel and to remount

it in the right position. It will not be an easy task but it will

be solvable. Unfortunately

the coiled springs by O&K tend to brake frequently with increasing

age. So far I used spiral springs as substitute, which were built

for heavy mining cars. Because the springs of the locomotives

are free visible, there was the goal to rebuilt new "old"

springs already for a long time. In order to receive a favourable

price, four orderers joined. So could be manufactured an accordingly

large number of springs (30). The

Unfortunately

the coiled springs by O&K tend to brake frequently with increasing

age. So far I used spiral springs as substitute, which were built

for heavy mining cars. Because the springs of the locomotives

are free visible, there was the goal to rebuilt new "old"

springs already for a long time. In order to receive a favourable

price, four orderers joined. So could be manufactured an accordingly

large number of springs (30). The  _

_ _

_

_

_

_

_

_

_