August 2003

Since spring there were done some other, essential workings at the RL3, but it will run self-propelling at the earliest at the "Day of memorials" in September. It's founded in the fact, that one of the axle bearings was fixed in his guidance and that's why the axle couldn't move in the suspension. Because of this fact the loco didn't have a correct running and one coupling rod forced. That's why it was necessary to disassamble the axes. By the way the brake would completely finished. Now only the fan and the electrical equipment is to replace.

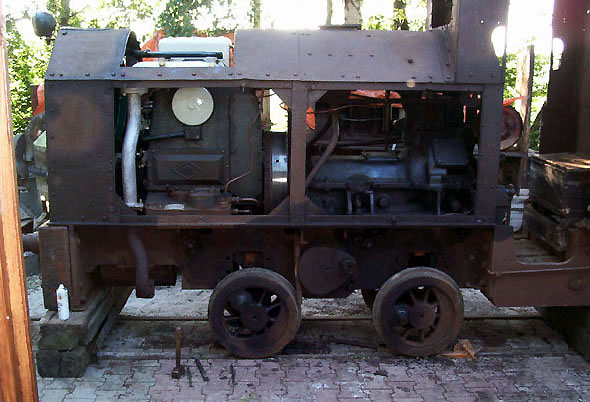

In the meantime the Deutz MLH514 was brought to Glossen and the heavy additional weights were mounted, with them the loco has a weight of 2,8 tons. Now the reconstruction is nearly ended. That the term "reconstruction" is actually entitled, comes to the fore with the comparison of the pictures from the finding situation and the recent state of the loco. At first the motor, the gear box and the buffers were absent and in 3 of the 4 axle ball bearings were no balls ...

_

_

March 2003

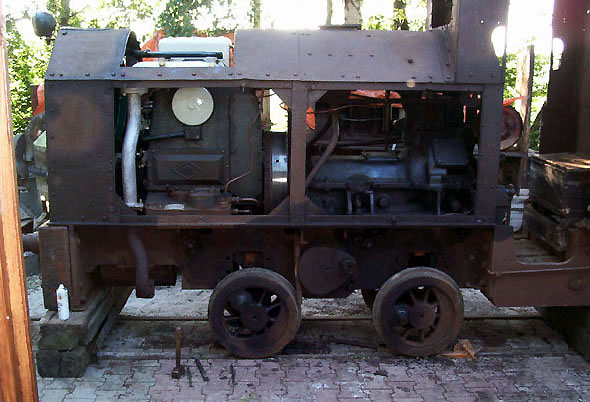

Just now the reconstruction of the "Montania" RL3 gets up to speed, it should be presented in action to public at Easter.

After staying without

use in an old brick yard building with leaky roof for 30 years

the corrosion made a "good" job at the loco. It weights

some kilogramms less than during it's operating days, especially

after the removal of the rust. All the parts of the loco are very

rusted, but the construction is so that there is enough material

at all. It isn't provided to sandblast and revarnish the RL3.

On the one hand for saving the authentic character and on the

other hand because the results of the corrosion will be observable

further on. The oiled, inner parts of the gear box and the engine

are in an excellent condition (gold-coloured oil!), the intermediate

shaft is easy turnable by hand. Unfortunately the comlepete electric

equipment of the locomotive isn't existing yet, it was disassambled

during the bad times after World War II. Of course the cruide

oil leading parts suffered from the long standstill, so the plungers

of the injection pump were fixed, the pressure of one oft the

nozzles was to low, the fuel tank was littered and so on. The

cylinder head had to work of: grinding the valve seats, loosing

the rocker arms ... After passing several times for this tasks

now the first success is to see:

At the 9th of March the engine (of course started by hand) was running the first time and it run very consistent! Salutatory it pushed out much grime and than it blowed out very beautiful rings of smoke.

Now it's to refurbish the cooling system and the bearing of the coupling rod yet.